Improving Project Controls Competency: 3 Common Barriers Organizations Need to Overcome

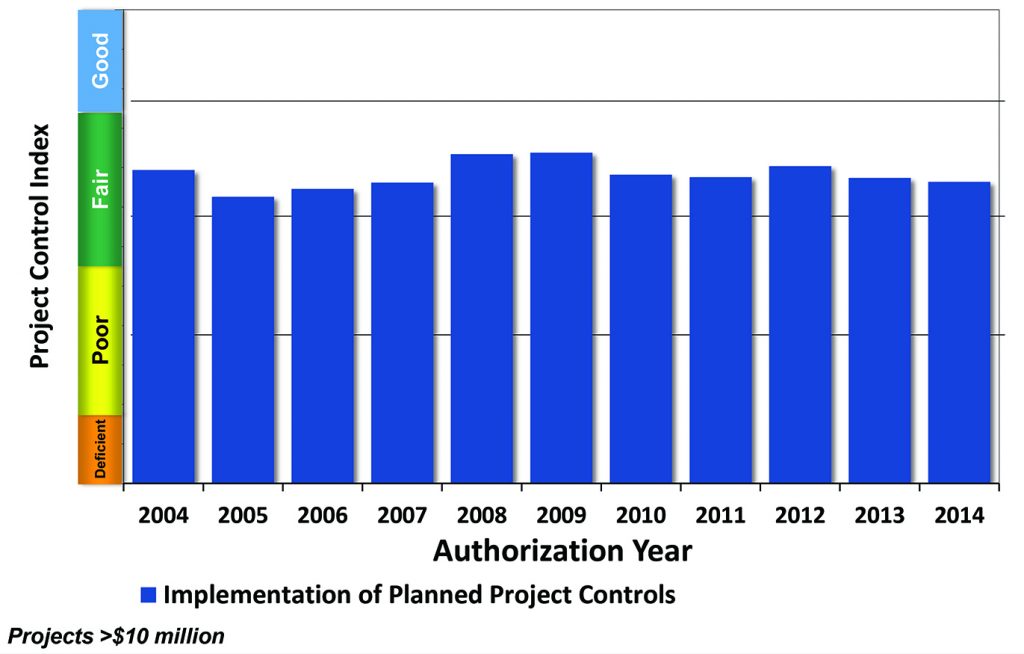

The capital projects Industry is stuck in a rut in terms of design and project controls use. Owner companies appear to recognize the importance of project controls, as planning for their use during the development of capital projects has increased some over the last few years. Unfortunately, owners are making no progress implementing project controls practices or strengthening their project team project control competency, thereby risking significant project execution cost growth and schedule slip. Research based on IPA’s proprietary capital projects database and its Project Controls Index (PCI) measuring owners’ planned and actual project controls practices sheds light on the industry’s struggles with improving project controls design and implementation (Figure 1).

Figure 1 — No Improvement: Industry’s use of project controls during the construction of capital projects has been Fair, as measured in IPA’s Project Control’s Index, going all the way back to 2004, according to IPA’s 2016 research into the implementation of project control systems.

IPA’s PCI classifies both the planned and actual use of project controls as Deficient, Poor, Fair, or Good based on project management practices that have a statistically significant relationship with project outcomes. On average, project controls in Industry have remained Fair for over a decade. This means project controls are not being designed to their full potential for their purpose in improving execution management. When projects do not follow through with their plans during execution, IPA research has determined that owners can expect their project to experience as much as 10 percent cost growth and 10 percent schedule slip from authorization. IPA set out to find out why owners are having such a difficult time improving their project control practices, given that previous IPA research has proven that project control competency is a capital effectiveness driver. In a study that included surveying more than 100 project control specialists representing dozens of owner companies in several industry sectors, IPA was able to identify three barriers that thwart project controls design and use.

Barrier 1–Under-Resourced or Non-Existent Project Controls Organizations

More than half of project control specialists surveyed said the project controls organization they belong to is inadequately resourced. A fifth of the respondents said they did not even belong to a structured project controls organization. Past IPA research has shown that project controls systems are less likely to be ready before execution and more likely to experience excessive influence from project managers during execution when there is no project controls organization in place or if the organization does not have the wherewithal to stand against management pushback. Project control specialists also cited insufficient independence and autonomy, understaffing, and lack of controls integration with project teams as resourcing gaps.

Barrier 2–Insufficient Project Controls Contract Requirements

Contracts are the legal documents where, among other things, project controls requirements need to be specified. When contract language pertaining to project control requirements is deficient, project controls run the risk of not being set up correctly. Of the project control specialists surveyed, 21 percent said contract clauses specific to project controls were vague and another 21 percent said they were unfamiliar with project controls details in contracts. Among the problems cited by project control specialists are the absence of requirements language, provisions devoid of important details, and unenforceable or unsuitable requirements. When contracts are inadequate, the project controls organization is left in a weakened state and at the mercy of contractors. Bad contracts open the door for inconsistencies, low-quality reporting from contractors, and extra work to make up for the lack of understanding/ specificity in the contract agreements. Notably, almost 40 percent of project control specialists said they do not provide input into the contracting process mainly because they are not invited to participate in the process.

Barrier 3–Deficient Project Control Implementation Processes & Tools

In response to the IPA survey, over 80 percent of project control specialists rated their tools and processes as deficient. Almost half of project control specialists said they have started a project’s execution phase with a project control system (including software, accounts set up, and mechanisms for measuring progress, etc.) that was not ready for use. As a result, they spend time setting up the tools when they are supposed to be using them. In essence, project control specialists are trying to tie their shoes while running the race—definitely not a good strategy for success.

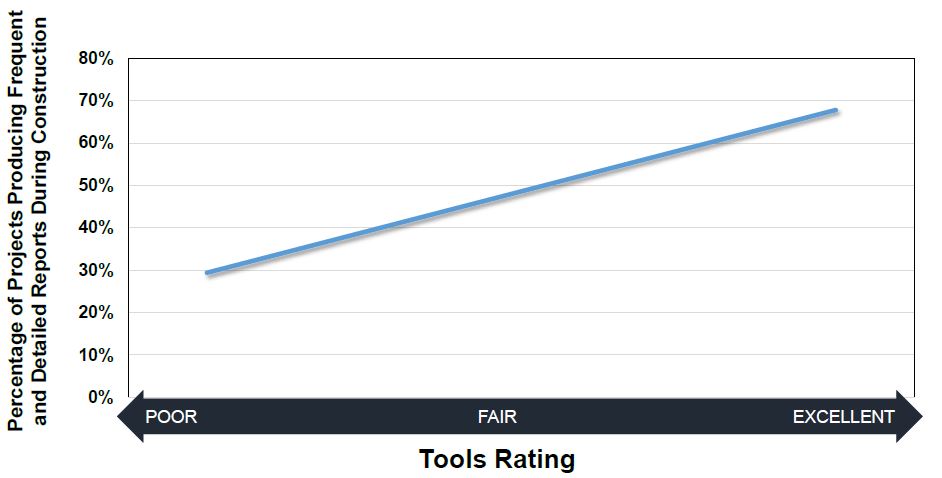

In addition, the poorer the rating project control specialists gave their project control tools, the less capable the tools were in creating regular and detailed reports for project managers (Figure 2), which is a known Best Practice. Project control specialists also reported dealing with deficient work processes that result in work duplication like generating reports with the same information in different formats to deliver to different stakeholders. Such challenges for project control specialists prevent project controls from being implemented efficiently and effectively.

Figure 2 — Execution Phase Report Quality: The ability to produce frequent and detailed reports is a function of the quality of tools.

How can we destroy or elude these barriers to project controls for capital projects? For a long-term improvement, owners should consider the following general guides:

- Create or define a project controls organization that ensures appropriate and early staffing and integrates the controls function into the team.

- Involve controls in the development and enforcement of contracts. This is critical to establishing and holding on to effective controls in execution.

- Develop or improve processes and tools that work across the system and that are supported by management and the project organization.

For coping with suboptimal conditions, IPA’s survey of industry project control specialists found that a proactive approach to controls design can provide some avenues to improvement. Some important strategies shared by our survey respondents include:

- Educating management on the importance of project controls, its staffing, inclusion in contracts, and alignment of stakeholders with processes and tools.

- Developing relationships with upper management, contractors, and the project team to help in dealing with all three barriers presented. For example, project control specialists might consider communicating, stepping-in, and helping contractors when they don’t know how to comply with contract requirements or helping them use tools and follow processes.

- Adapting behaviors, processes, and tools to certain situations, by, for example, developing tools to deal with incoming data in different formats, and exploring other ways of dealing with the common challenges project control specialists face in their day-to-day work.

By identifying and understanding the barriers to effective project controls implementation, it is reasonable to expect that the entire capital projects Industry can move from the PCI’s Fair to Good (Best) classification of performance. This research is part of a series of studies on functional competency within project teams.

Special thanks goes to the project control specialists who participated in the survey, shared their insights, and made this effort possible.