CCUS Industry Insights Provide a Foundation for Future Projects

More than ever, capital projects are being implemented with emissions reductions at the forefront. Among the most impactful options for reducing greenhouse gas emissions is Carbon Capture, Utilization, and Storage (CCUS). CCUS projects allow for a reduction of CO2 emissions from both new and existing assets across a wide variety of sectors, including hard to abate sectors, such as steel and cement manufacturing. As regulatory entities, investors, and shareholders further drive the demand for emissions reduction, CCUS projects are poised to play an important role for decades to come. IPA’s recently established CCUS industry insights and performance metrics will help companies prepare for the challenges that lie ahead.

Relatively few CCUS projects have been completed to date, with many projects canceled or put on hold after they have been announced. Sponsors stop projects because they cannot reduce risks to an acceptable level before full-funds authorization. Contributing to this risk is CAPEX and technology performance uncertainty. There is a lack of CCUS project data and corresponding CCUS industry insights from early facility operations. This hinders decision making at all steps—from early opportunity screening to shaping project development strategies that effectively reduce risk and uncertainty.

Although a handful of CCUS cost studies have been executed,1 these studies rely heavily on assumptions and idealized scenarios rather than data that exist from real-world examples of CCUS projects. To address the limitations posed by having a small number of completed CCUS projects, IPA has aggregated available CCUS project data to establish cost and schedule norms across the core scope elements of CCUS projects.

The CCUS cost and schedule norms help avoid the sunk costs from projects that are canceled late in the project development cycle. Clients can use the results to develop conceptual estimates for different options in the CCUS value chain in a project or they can validate their own cost and schedule estimates. Both activities allow companies to screen out projects for which the CAPEX is too high or uncertain to justify additional investment.

IPA’s CCUS Database

IPA’s recently completed CCUS Performance Norms Study aggregates data from 26 CCUS projects, accounting for over 70 MTPA of CO2 from completed projects and those in development. These data are used to provide cost and schedule metrics and a technology assessment for CCUS projects that can empower decision makers with the knowledge they need to drive the successful development of CCUS projects.

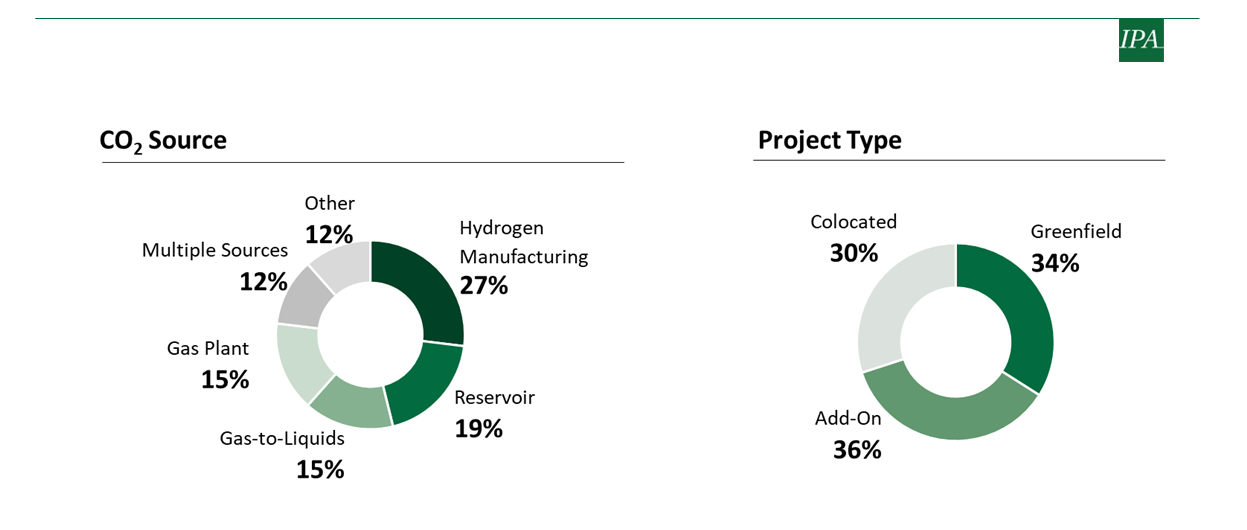

The database from this study, shown below, encompasses many of the characteristics that make CCUS such an important abatement option. Among the advantages of CCUS is the ability to retrofit CCUS to capture emissions from existing facilities, which accounts for two-thirds of the projects in our dataset. In addition, the International Energy Agency (IEA) has highlighted CCUS as an enabler of low-cost, low-carbon hydrogen production. The importance of CCUS in hydrogen production is evident in IPA’s CCUS study; over one-quarter of the dataset projects have hydrogen production as the CO2 source, accounting for a total of 18 MTPA of captured CO2.

The scale of CCUS projects varies widely; the smallest projects in our database are designed to deliver less than 0.5 MTPA and the largest almost 10 MTPA. IPA’s study found that a typical CCUS project requires a CAPEX investment of about $500 million (2023 U.S. dollars) to build the capacity to capture, compress and dehydrate, transport, and inject 1 MTPA of CO2. However, the costs vary and are driven by several factors, including location and the technology used for each component of the value chain.

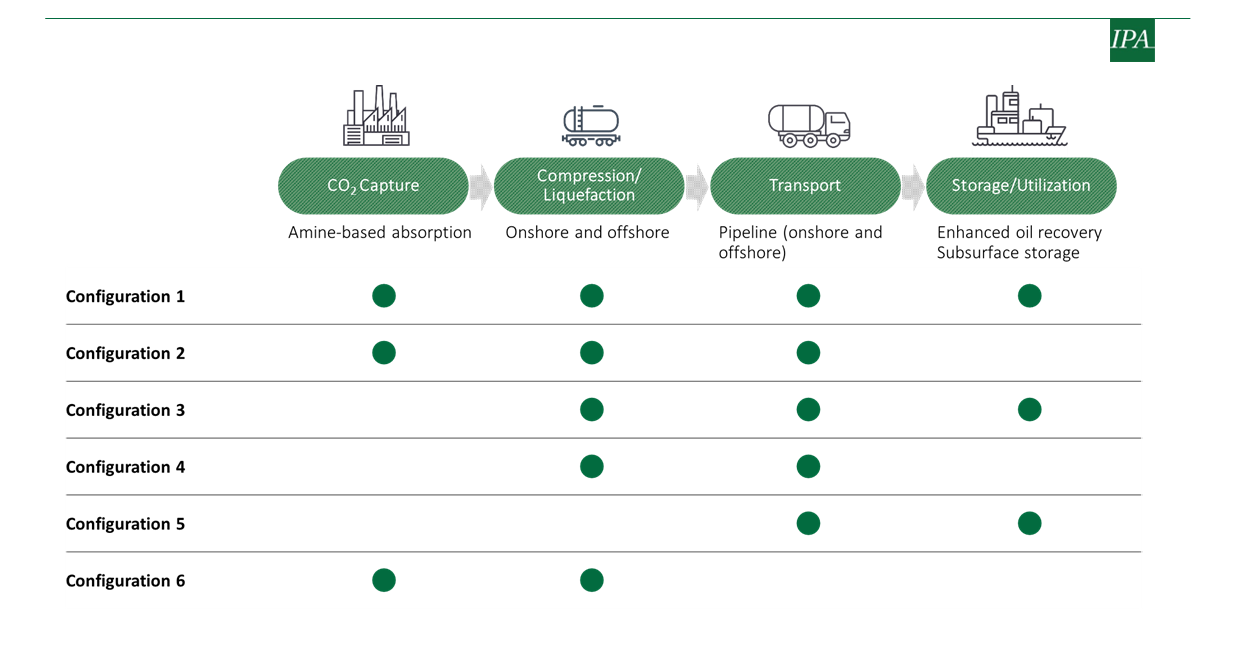

IPA breaks the CCUS value chain into the four components show below: capture, compression and dehydration, transport, and storage. Metrics are presented for both the overall CCUS asset and individually for each component for the study. Asset-level metrics apply to projects with all four components, encompassing the entire CCUS value chain. The breakdown into component-level metrics is of particular value as not all projects have all components. About one-quarter of the projects in the study include all four components, half include three of the four components, and the remainder include two of the four. The different configurations of components for the projects in the study are shown below.

CCUS Metrics

The capture and compression of CO2 makes up about three-quarters of the total cost of the full CCUS value chain, making it crucial to understand the drivers of the costs of these components when considering the overall asset. Both components benefit from economies of scale for higher capacities of CO2. As expected, the percentage of CO2 in the feed gas (a factor determined by the source of CO2) is an important driver of CO2 cost. The current industry standard for CO2 capture is amine absorption; all projects in our study dataset used such. However, many capture units—both amine absorption and other technologies—are being touted as “off the shelf,” despite not having been tested in the specific setting they are proposed for. Indeed, guarantees of progressively higher CO2 capture rates have been made, despite a lack of supporting evidence. The current lack of completed CCUS projects prevents a better evaluation of these claims, and the industry will greatly benefit when the performance results of these new technologies are known.

For CCUS projects with all four scopes present, transport and injection costs tend to represent the smallest portion of CCUS costs; typically, less than 20 percent of the combined CO2 pipeline costs are driven by typical pipeline drivers (i.e., length, diameter, and wall thickness). The injection well costs, although correlated with CO2 injection capacity, are more closely associated with program characteristics, such as the number of wells and well depth, as shown in this study.

Challenges in Development of CCUS Projects

Like any other project, CCUS projects face challenges, including new technology performance and/or new integrations of existing technologies. As a rapidly developing sector, it may be difficult to judge how much the cost will decrease as the capture technologies continue to be implemented in CCUS projects. IPA’s technology assessment of capture technologies focuses on amine absorption and cryogenic separation. Learning curves developed from analogous technologies are used to provide an outlook on how costs may change in the future.

Outlook for the Future of CCUS Projects

The CCUS sector is in the early stages of a dramatic expansion and project teams and systems across the world are looking for real CCUS industry insights and project data to inform strategic decision making and support project planning. The metrics established in IPA’s study build a foundation to meet this need. Each metric reflects the cost and schedule performance and technical characteristics of today’s projects and their constituent components.

The success of future CCUS projects depends on understanding the actual performance of completed projects. As more projects are executed, this database—and the depth and breadth of the metrics at our disposal—will grow commensurately, allowing for updates to the CAPEX, schedule metrics, and operational performance. We will also add to our current suite of metrics, including data like operating costs, and identify practices that promote successful outcomes of CCUS projects.

1 Global CCS Institute, Global Costs of Carbon Capture and Storage 2017 Update, June 2017, Accessed July 26, 2021, https://www.globalCCSinstitute.com/archive/hub/publications/201688/global-CCS-cost-updatev4.pdf; National Petroleum Council, Meeting the Dual Challenge: A Roadmap to At-Scale Deployment of Carbon Capture, Use, and Storage, December 19, 2019, Accessed July 23, 2021, https://dualchallenge.npc.org; Electric Power Research Institute, Towards Improved Guidelines for Cost Evaluation of Carbon Capture and Storage, April 2021, Accessed July 27, 2021, https://www.epri.com/research/programs/0TIZ12/results/3002021990; Global CCS Institute, Technology Readiness and Costs of CCS, March 2021, https://www.globalccsinstitute.com/resources/publications-reports-research/technology-readiness-and-costs-of-ccs/.