Low Cost and Low Carbon Are Not Mutually Exclusive

As companies strive to lower their greenhouse gas (GHG) emissions from hydrocarbon‑producing assets, most anticipate having to spend more to achieve their goals. Companies expect the CAPEX of their capital projects to increase as they try to meet the lower emissions target set by stakeholders. While this might be true for reducing emissions from existing assets—which have already some locked in equipment or design that needs to be replaced—trends emerging from IPA research show that this does not necessarily have to be true for new greenfield developments. Cost and carbon competitiveness are not mutually exclusive: both are achievable at the same time.

To achieve this, the two fundamentals of capital projects remain the same:

- Adopting industry Best Practices during project selection, shaping, and development will significantly improve the project performance.

- Decisions made earlier in the project journey have a greater influence on outcomes, and this ability to influence project outcomes decreases as the project is further defined.

The key questions are: What emerging Best Practices positively influence the journey toward a lower cost and lower emissions project? And how do you adapt the existing stage-gated project development process to include these new practices?

Measuring Carbon Competitiveness

Working with members of the IPA Carbon Working Group, IPA developed standard frameworks to collect emissions data at the project level for all hydrocarbon producing asset classes. This standard emission breakdown structure is used to collect data related to Scope 1, Scope 2, and project-related Scope 3 greenhouse gas (GHG) emissions.[1] Similar to IPA’s Cost Index, using the robust database of Scope 1 emissions profiles provided by individual project teams, IPA has developed benchmarking methodology to assess the Life of Field Carbon Intensity Index. This methodology benchmarks the emissions performance of any particular project relative to other projects in the industry with similar field development and design characteristics.

In addition to emissions performance, IPA also collects details about the project practices at each decision gate in the project development cycle. The Carbon Readiness Framework highlights gaps in the practices of any particular project team and measures the readiness of that project team to move to the next phase of development. This framework includes detailed assessment of practices and decisions related to low-carbon target setting and Key Performance Indicator (KPI) balancing, calculation of accurate and comprehensive emissions estimates, inclusion of carbon pricing, response to regulatory requirements, and startup planning.

The above metrics and frameworks help project teams evaluate the competitiveness of their emissions performance. Project development practices ultimately deliver (or fail to deliver if not followed) on the potential that opportunity presents.

Lessons From Early Adopters

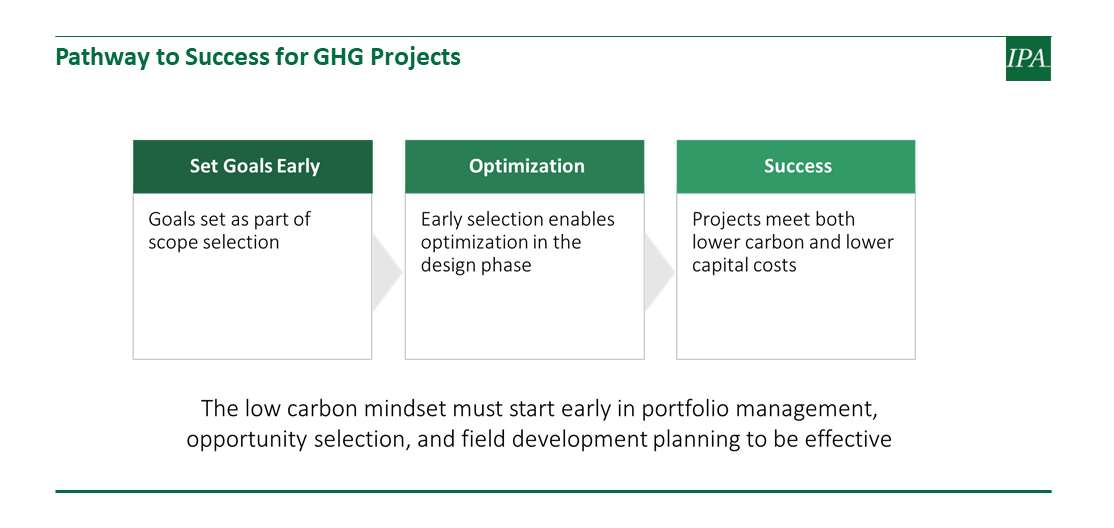

To successfully reduce carbon emissions—without adding significant cost—the low carbon and low cost mindset must be adopted early in opportunity screening, concept selection, depletion planning, and scope selection. This low carbon/low cost mindset continues into technology selection by optimizing and selecting the Best Available Technology (BAT) to meet the project targets. This journey usually focuses on decisions in three arenas:

- Use design optimization and BAT selection to reduce energy demand

- Choose cleanest form/source of energy to service remaining energy demand

- Deploy carbon reduction and carbon removal scopes to address the remaining GHG emission

In this manner, effective opportunity screening and scope development sets a solid foundation for reducing carbon intensity of the asset for the entire life of the field.

It Is an Optimization Exercise

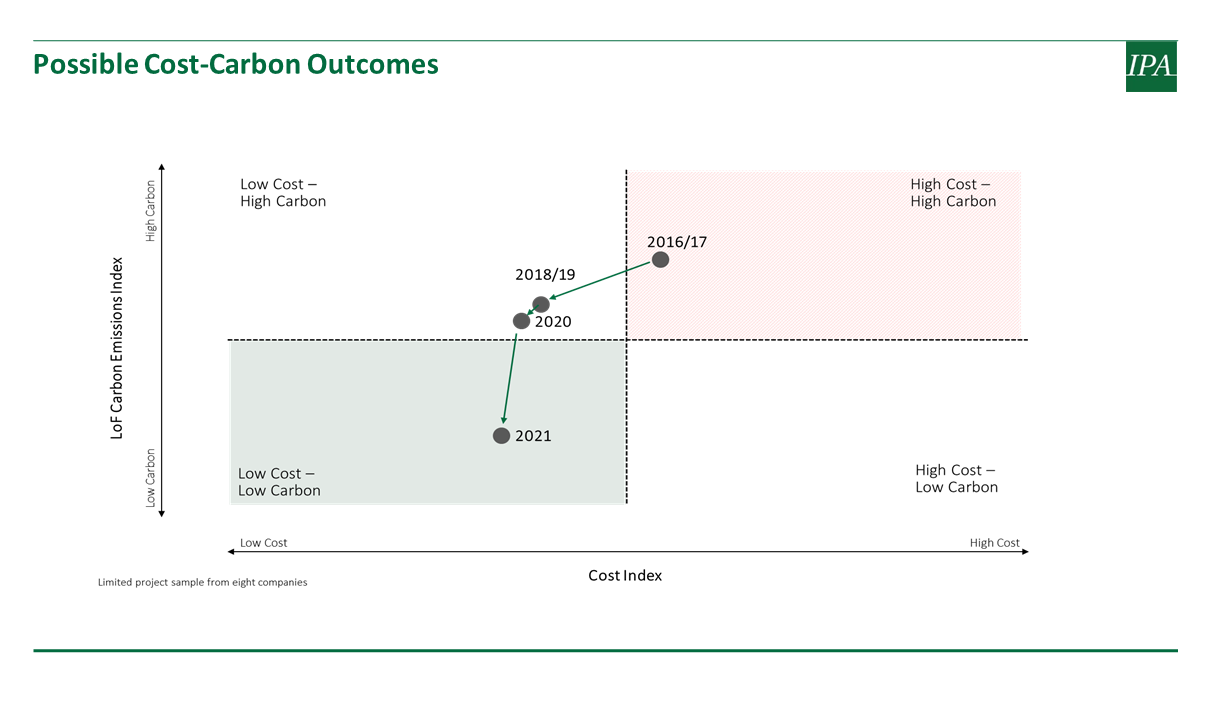

As shown in the figure below, there are four possible scenarios with regard to cost and carbon competitiveness. At worst is a project that has both high costs and still has high carbon emissions. IPA’s evaluation of cost and carbon competitiveness of recent projects has found that projects did, at first, fall into that top right quadrant of both high cost and high emissions. With dedicated efforts to reduce emissions, what early adopters anticipated is shown in the bottom right quadrant—low emissions but at a high cost. However, a project that is able to achieve both low costs and low carbon emissions is possible. In response to their poor cost and carbon performance, some of these early adopters are now setting more aggressive emissions targets for their projects and establishing practices and work processes to optimize this cost-carbon balance.

Based on research presented at Upstream Industry Benchmarking Consortium (UIBC) meeting in November 2021, the early adopters are now able to achieve improvements in cost and carbon competitiveness as a result of significant mindset changes. These companies now routinely execute projects that are both low in cost and low in carbon emissions.

Three Examples of GHG Emissions Reduction Efforts

In our research, we have come across projects that have ranged from missing the mark on both cost and carbon to successfully achieving competitive targets in both KPIs. Below, we explore three examples of GHG reduction efforts that illustrate the range of experiences.

In our first example, the GHG reduction KPI was not identified until Define, after a post-COVID-19 restart in this phase. Thus, this project did not apply GHG practices until mid-definition, which is not early enough. During the extended Define phase, the project team changed the power generation strategy, reducing carbon emissions. Although energy efficiency and safety benefits were also captured, the project remained 28 percent more carbon intensive than average (and the cost was slightly higher than average as well).

The second example involves a project that was part of a series. Projects in a series typically achieve cost efficiencies as the program progresses. This project fell in the middle of the program and that is when the organization established its corporate GHG goal. The project was successful in its GHG aspiration. The team was able to reduce CO2 emissions by 35 percent relative to the previous project in the series. However, cost competitiveness degraded by 7 percent.

In our final example, the project was able to achieve both a competitive cost (9 percent lower than Industry) and good carbon performance (22 percent better than Industry). In this project, cost and carbon targets were quantified early in the definition phase, allowing the team to develop a scope that was both low carbon and low cost.

As these examples illustrate, decarbonization must be at the forefront of decision making to be successful. To work toward meeting emission reduction goals, companies need to evaluate the positive and negative contribution of each opportunity and scope choice toward that goal. As shown above, low cost and low carbon outcomes are attainable in a single project. However, the low carbon mindset must start early in portfolio management, opportunity selection, and field development planning to be effective.

IPA continues to evaluate projects under development and research the drivers of optimal low-cost and low-carbon performance. For more information about how companies are achieving this optimal performance, please fill in the form below.

[1] Scope 1 emissions are direct emissions from within the operational boundary of the project. Scope 2 emissions are indirect emissions due to import of power, heat, or steam to the project. Scope 3 emissions are indirect emissions from other sources, including emissions due to third party activities, the supply chain, and use of products.