Mitigating Risks of Early Commitment in New Energy Projects

Because of their characteristics, business often commits to new energy projects early in their life cycle, which increases the risk of project failure. Understanding and mitigating the risk of these early commitment projects is key to their success.

What Are Early Commitment Businesses?

For most industrial projects, especially those producing commodities, the precise timing of when the business commits to a project is a matter of corporate governance regarding risk. Most industrial projects are committed at the end of scope development and before front-end engineering and design (FEED). The final investment decision (FID) is taken after FEED, but the actual decision to proceed happens at the end of scope development and is only reversed at FID if something fundamental has changed.

A few industrial businesses, however, are routinely required to make binding commitments to a capital project before the end of scope development because they are in a bidding competition. These businesses include air separation, hydrogen supply projects, pipeline projects based on competitively bid tariffs, some solar photovoltaic projects, and some wind projects. When a business has to commit to a project prior to full completion of scope development, substantial risk is added to the project. It is important to understand and mitigate that risk early so that a more precise estimate can be established as the basis for the early commitment decision.

Early commitment is not fast tracking. Although business commits to an opportunity during scope development, these projects complete the remaining definition activities after commitment to continue minimizing risk prior to beginning execution. In contrast, fast track projects skip definition activities and often merge assurance gates in hopes of achieving faster front-end work and the ability to start execution sooner. These projects have much higher risk profiles than projects with all front-end work completed.

What Does the Early Commitment Project Development Process Look Like?

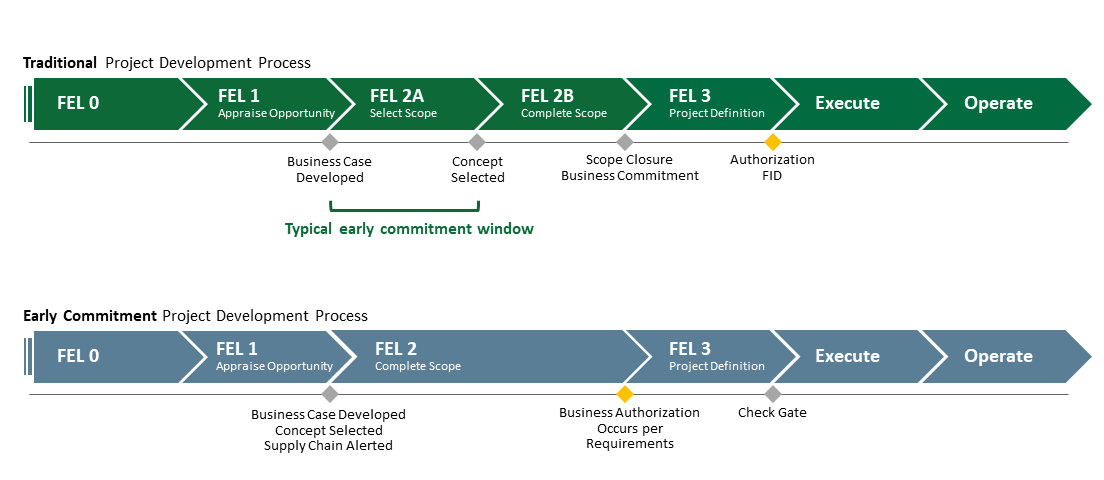

Traditional projects follow a stage-gated approach that includes Front-End Loading (FEL) 1, in which the team appraises the opportunity before selecting the scope at FEL 2A. Scope development is completed in FEL 2B, followed by FEED activities and FEL 3 such as execution planning. If the governance process is working, decisions are made at the gates that separate these phases. Business commitment happens at the end of FEL 2B and the final investment decision (FID) is taken at the end of FEL 3.

As shown below, for early commitment projects, the typical commitment window comes earlier—normally between the end of FEL 1 and the middle of FEL 2. Thus, at FEL 2A, when the scope would be selected for a traditional project, the business is already committing to these early projects. Early commitment projects cannot get through the entire scope development process before that early business decision has to be made. Getting through both FEL 1 and 2 before the authorization decision is the best case scenario, but often projects only complete about one-third to one-half of FEL 2 before business needs to commit to a project cost and schedule estimate. The earlier the commitment is made, the higher the risk. Because commitment occurs earlier, the FEL 3 gate becomes a check gate to ensure the project is prepared to execute.

Business Authorization Happens Sooner for Early Commitment Projects

What Are the Key Elements to Reduce Risk?

Committing to a project before the end of scope development adds substantially to the risk of cost growth and schedule slip. The amount of risk added depends greatly on the portion of the scope that is fully standardized. Early commitments without a standardized scope are likely to be failed projects, unless they are very high return projects. Unfortunately, renewables projects subject to reverse auction bidding tend to be low return projects with moderately high risk. They compete with utility projects that are largely done with guaranteed returns on capital. When returns are low, even a modest cost overrun can render a project NPV negative.

Early commitment projects face risk because of the unknowns they include at the time of business commitment to the project. The biggest risks leading to potential value loss during the maturation of an opportunity include shaping, supply chain, and technology. The more unknowns a project has, the higher the risk it faces. Thus, it follows that reducing the project’s unknowns reduces the risk. What are the key elements for project teams to do this?

One way is to use as much standardized design as possible. On typical early commitment projects, 60 to 80 percent of the total project cost is based on fully standardized kit—and the supply chain for that kit is fully developed and subject to binding commitments if the bid is won. Leveraging standardized design allows projects to move much more quickly through FEL than traditional projects.

Another key to risk reduction is to quickly identify and evaluate the portion of the project that cannot be standardized, as well as potentially risky local conditions. This includes:

- The regulatory regime and how it affects schedule

- Site conditions like soils and hydrology

- Local logistical challenges such as access and materials management

- Permitting, bonding requirements, local content requirements, etc.

What Work Process Changes Are Required?

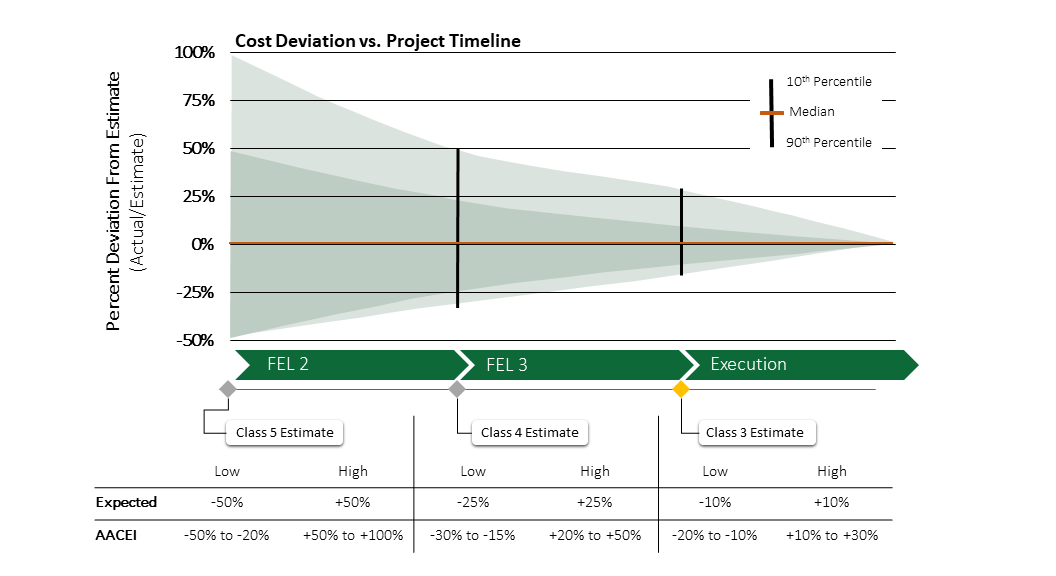

As projects progress through FEL, cost accuracy improves (see figure below). For early commitment businesses, project definition activities must be moved up to enable development of more precise estimates during FEL 2 in support of these commitment decisions—the work process is adjusted to get essential work done in the time available (everything that is non-standard). In general, key activities are moved up one stage. No activities are eliminated as part of the front-end work and the importance of each activity remains the same—some activities are simply done earlier. Although the sequencing of activities is not ideal, it is the best that can be accomplished within the constraints of early commitment.

As Projects Progress Through FEL, Cost Estimate Accuracy Improves

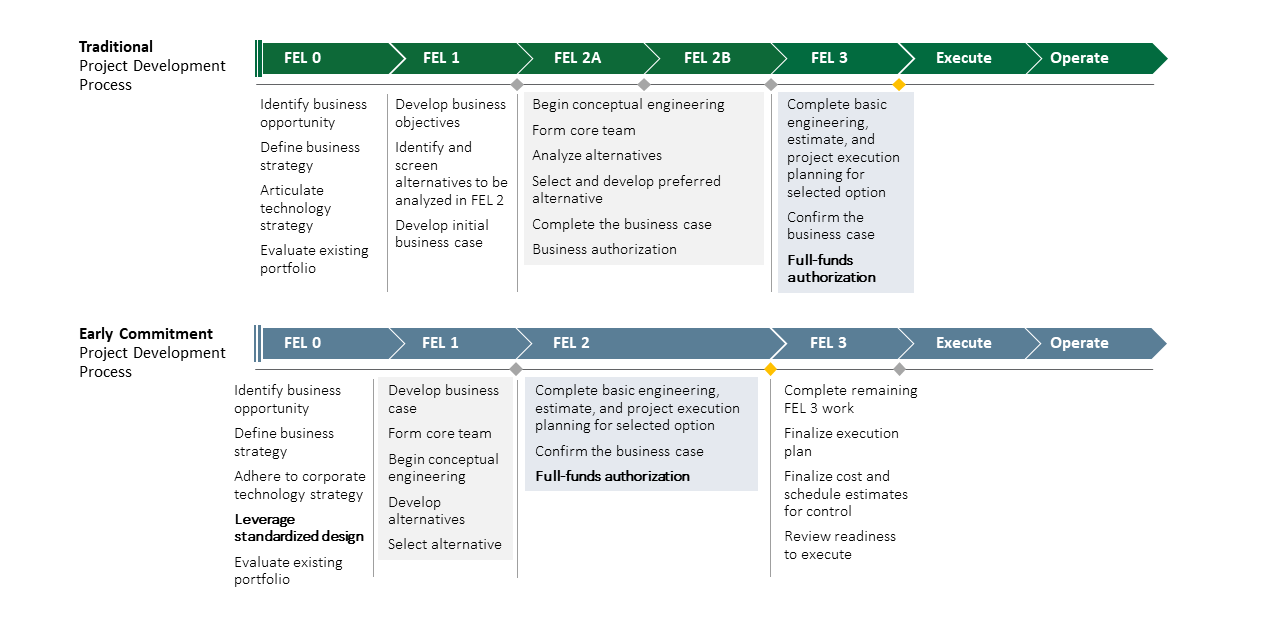

As shown below, in early commitment projects the core team is formed and business case established in FEL 1 instead of FEL 2. The scope alternatives are developed, concept selected, and conceptual design begins in FEL 1, not in FEL 2. The team then develops a project execution plan and cost and schedule estimates that consider all site-specific risks in FEL 2, and prepares the project for full-funds authorization during this phase. Several characteristics of early commitment projects position them for success in execution.

Most FEL Work Shifts One Phase Earlier for Early Commitment Projects

Leverage extensive FEL 0 work. Standardized design allows projects to enter FEL 1 with a more comprehensive and complete FEL 0 package. Standardization enables pre-defined scope for viable options, already complete Value Improving Practices for standardized elements, technology evaluation that is mostly complete, and a standard supply chain that can be initiated early.

Form an integrated cross-functional project team in FEL 1. This typically happens in FEL 2 for traditional projects, but for early commitment projects, the core team should be assembled around the middle of FEL 1. More experts and specialists can be added to the team in FEL 2.

Investigate and evaluate all potential project killers first. All sources of cost growth outside the standard kit are evaluated to the extent that time allows. The extent of risk reduction and its implications are communicated to the business sponsor in real time. The team then does as much work as possible and communicates the remaining risks so business can make an informed decision on whether to move forward.

Fully understand the site requirements. This is critical to risk reduction for early commitment projects and the minimum requirement to make an early commitment. Site issues are the one thing that could kill the project because they cannot be standardized. For early commitment projects, the site investigation initiates in FEL 1, rather than FEL 2.

Maintain the discipline to complete FEL once the project is approved. Continuing the FEL work, locking in the design basis, finalizing all the planning, and getting estimates to a control-grade level is still important after the full project commitment is made. The check gate at the end of the traditional FEED period ensures the project is ready for execution. If the business sponsors have low regard for the project work process or if governance is weak, projects start execution without complete FEL work, with disappointing results, especially for low-return early commitment businesses.

Employ strong governance. A governance process must be in place, and must be adhered to and strictly enforced through the projects organization. Do not skip FEL requirements and do not merge assurance gates.

Leveraging Strategies at the Portfolio Level

What leveraging strategies can companies use at the portfolio level to position themselves for success in early commitment projects? The more work done at the portfolio level, the better positioned the project will be going into FEL 1. Having more FEL 0 work done is one of the ways to gain some speed as project teams are defining these opportunities.

First, establishing effective resourcing strategies creates a solid foundation for projects early in development. Because FEL 0 is more defined than for traditional projects, companies are able to capitalize on FEL 0 activities by establishing an FEL 0 program for every early commitment technology. This is analogous to an exploration process for renewables businesses. These FEL 0 teams develop basic data and information for a particular technology, agree on the concepts and viable scope alternatives, develop a standardized supply chain, and then continuously look over that portfolio for opportunities to invest.

The other thing that companies can address in terms of resourcing at the corporate level is in the approach to the make-up of the front-end team. Companies could develop a staffing model for each type of renewables project in which a core team completes early FEL 1 work to develop the business case. In this scenario, FEL 1 can move forward much more quickly because no time is required to establish the initial working team. A small integrated cross-functional team is formed in the middle of FEL 1 to continue with the project’s scope development.

For each renewables business, companies need to select a technology strategy. There are two basic strategies to choose from at the corporate level. The first strategy is to innovate continuously. This means a company is always seeking to be on or close to the cutting edge. To maintain this strategy, companies need people who are up to date on technical innovation. The alternative is to adopt a technology model, standardize it, work the supply chain around it, and then innovate only in the background until the company is ready to launch the next model or version of the technology.

Either approach is workable, but each carries its own risk profile and level of investment. Continuously innovating provides higher risk projects and a harder to standardize supply chain with a high level of technology investment, but ensures that the company’s technology is competitive. For the second model, however, companies risk being left behind if the technology is so fast moving that innovation rapidly makes last year’s technology uncompetitive. The upside is that lower investment is required for this approach.

The only approach that is completely unworkable is for companies to make no strategic choice. Doing nothing means each new development will be a technology selection crisis with insufficient time to make a considered decision. Companies need to develop a strategy to follow most of the time.

Companies can standardize activities at the portfolio level to position projects to enter FEL 1 with a more complete FEL 0 package. By pre-baking as many decisions as possible, project-specific definition activities are reduced and individual risks are mitigated more quickly. Several areas mentioned previously present opportunities for corporate-level standardization: opportunity assessment, technology development strategy, overall supply chain or key supply chain elements, and project team staffing model. In addition, the maintenance approach—to the extent that it affects capital—can also be standardized.

Modifying the work process at the corporate level can help teams move more efficiently through the definition of the project opportunity and position early commitment projects for successful execution.

Running some project steps in parallel is one strategy. As mentioned earlier, all definition steps are important—none should be eliminated from the definition workflow. However, some steps can be done concurrently to finish the work more quickly. Doing things in parallel in the pre-bid period helps projects get to a decent level of definition before the company submits a bid.

It is also important to establish a pacing strategy at the portfolio level. Teams need to understand how quickly they can move through definition of key issues. Each business could rework a definition roadmap and apply it to its specific opportunities.

Another strategy to optimize time and further minimize risk is to use the downtime after bid submittal to complete more definition work. At the same time, the company has to evaluate risk versus reward and consider how to lower the risk profile while not putting too much work into it in case the project does not move forward. If this additional definition work does not plug gaps open at the time of bid and significant risk remains, the company should consider withdrawing the bid if the contest allows.

Do you need help with mitigating risk in your early commitment projects? Complete the form below to start a discussion with IPA.